摘 要

本论文主要研究的是应急灯外壳注塑模具的设计方法。本文首先介绍了选题的依据以及选这个课题的意义,并简单介绍了注塑模具的发展现状。然后分析了应急灯外壳制件的工艺特点,包括结构工艺性、成型特性与条件、材料性能等,并选定了成型设备。接着述说了应急灯外壳注塑模的分型面选择、模具基本结构及模架的选定及型腔数目的选定及布置,重点论述了成型零件、浇注系统、、脱模机构、合模导向机构以及冷却系统的设计。而后选定标准模架和模具材料,并校核注射机的相关工艺参数,如最大注射量、注塑压力等。最后阐述模具的工作原理,以及对安装运行过程中可能出现的问题予以总结、分析,并给于了对应的解决方法。

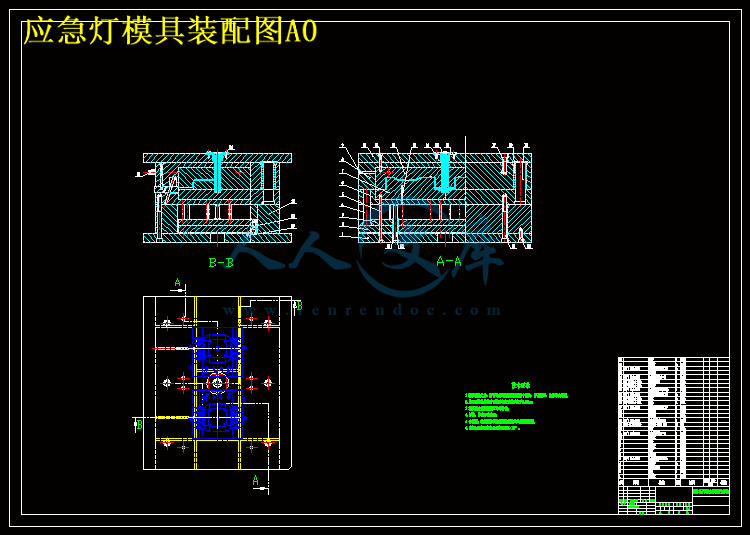

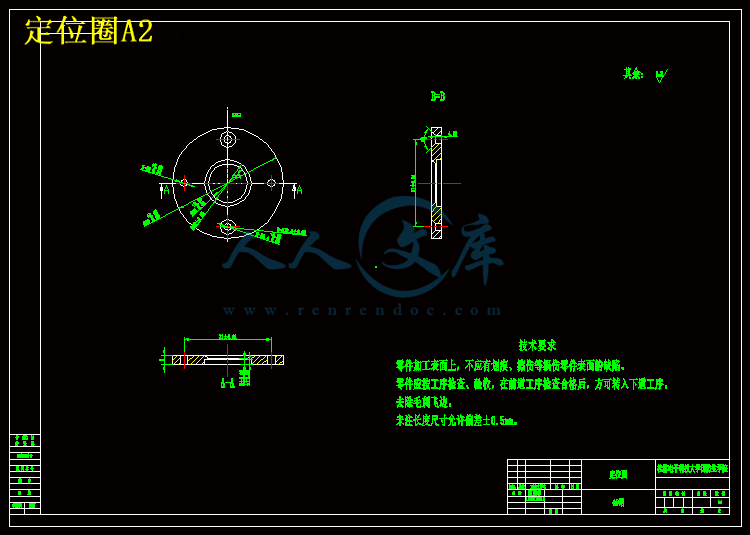

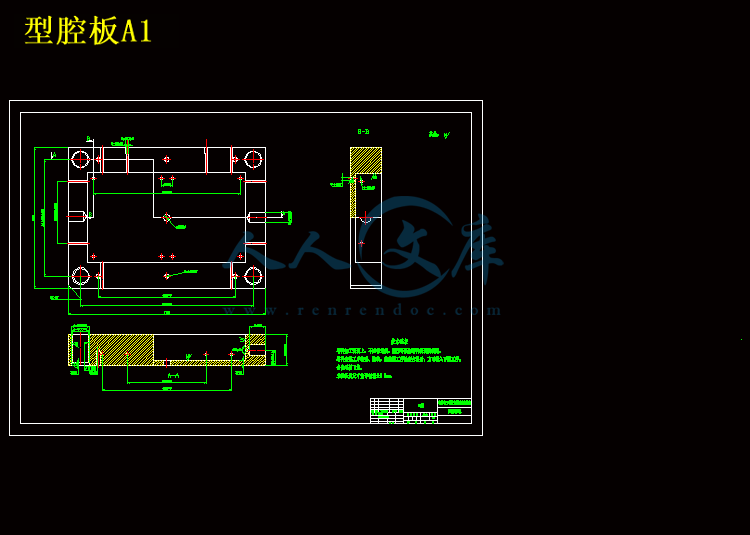

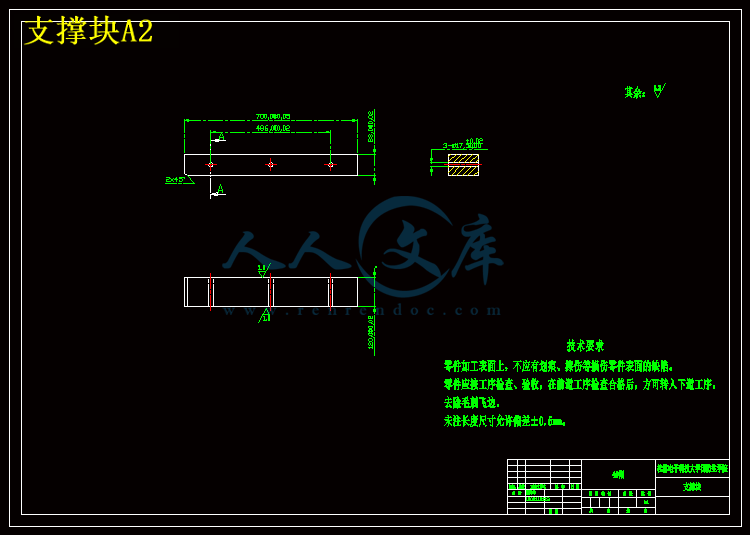

本文论述的应急灯外壳注塑模具采用两板式结构,采用一模两腔的型腔布置,最后通过推板将制件推出。在设计模具的时候,需用到SoliWorks软件进行模拟,以确定型芯型腔及浇口位。此次应急灯外壳注塑模具的设计各项参数必须来源可靠、选择准确、计算无误,其中最大注射量及注射压力是计算的关键。在工艺性上保证不影响操作的同时尽量做到了加工操作简单、方便。

本设计是在传统的应急灯上进行了创新,设计采用最领先技术LED显示,并把电池装在灯内部,外部也更美观。外壳的尺寸大小适中,模架也较好的选择,模具整体不大,采用整体安装。

关键词:应急灯外壳;注塑模;两板模;浇注系统;脱模机构

Abstract

The designing methods of injection mould of the Emergency light shell are mainly introduced in this paper. This paper introduces the topic basis and the significance of choosing thistopic, and briefly introduces the development status of injection mold.And then analyzes the process characteristics of emergency lamp shellparts, including the structure, characteristics and conditions of moldingprocess, material properties, and select the molding equipment.Then tell the type emergency lamp shell injection mold, mold surfacestructure and mold base selection and the number of cavities selection andlayout, emphasis, gating system, forming parts, demoulding mechanism,clamping mechanism and the cooling system design.Finally the selected standard mold and mold material, and process parameters of injection machine check, such as the maximum injection volume, injection pressure etc.. The working principle of the die, as well as to the possible problems in the process of installation and operation are summarized, analysis, and give the corresponding solutions.

Shell of emergency lamp injection mold in this paper adopts two plate structure, the layout of the cavity of a mould with two cavities, the push platewill work out.In the design of mold, use the SoliWorks software to simulate, in order to determine the core and cavity and runner position.Must choose accurate, reliable, accurate calculation of design parameters of the emergency lamp shell injection mold, the largest injection quantityand injection pressure is the key.In the process that does not affect the operation at the same time as far as possible the process has the advantages of simple operation, convenient.

This design is the innovation in the emergency lights on the traditionaldesign, using the most advanced technology of LED display, and the battery installed in the light of internal, external and more beautiful.Moderate size of shell mold, is the better choice, overall not die, the wholeinstallation.

Keyword: Emergency light shell;Injection mould;Threepence mould;Gating system;Moulding mechanism ; Space parting institutions

目 录

引言 1

第1章 应急灯外壳工艺性分析 4

1.1 材料性能 4

1.2 成型特性和条件 4

1.3 结构工艺性 4

1.4 产品几何形状分析 5

1.5 应急灯外壳注塑工艺参数的确定 9

1.6 初选注射机的型号和规格 9

第2章 应急灯外壳注塑模具的结构设计 11

2.1 分型面的选择 11

2.2 确定模具基本结构及模架的选定 12

2.3 确定型腔的数量和布局 12

2.4浇注系统设计 13

2.4.1主流道设计 13

2.4.2 分流道截面设计及布局 14

2.4.3 浇口设计及位置选择 15

2.4.4 浇口套的设计 16

2.5 注塑模成型零部件设计 17

2.5.1 成型零部件尺寸分析 17

2.5.2塑件收缩率的影响 17

2.5.3型腔、型芯结构设计 18

2.5.4 成型零件工作尺寸计算 20

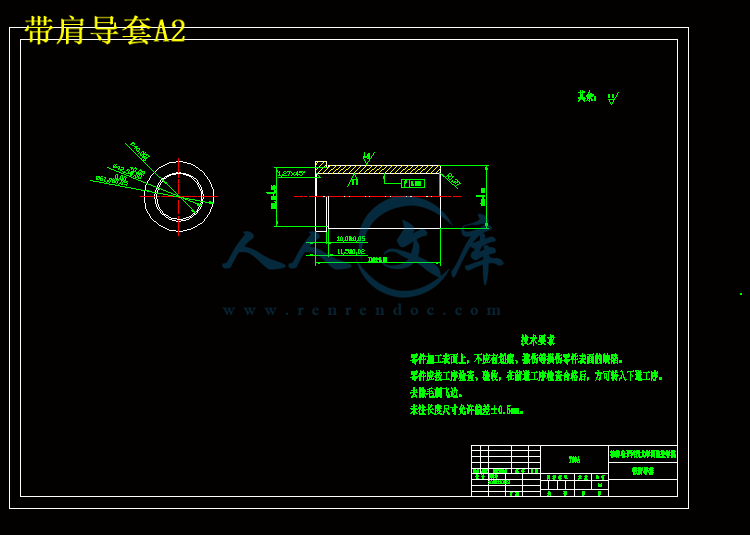

2.6 合模导向机构设计 20

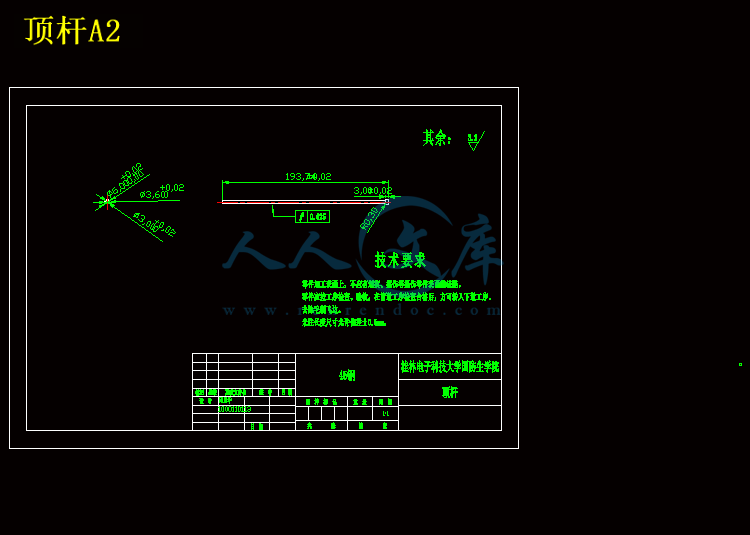

2.7 脱模、推出机构设计 21

2.7.1 推出机构的组成 21

2.7.2 推出机构的分类 21

2.7.3 推出机构的设计原则 21

2.8冷却系统设计 23

2.9 模架及模具材料的选择 24

第3章 注射机相关参数校核 25

3.1 最大注射量的校核 25

3.2 注射压力校核 26

3.3 锁模力校核 26

3.4 模具厚度的校核 26

3.5 成型零部件强度校核计算 27

第4章 模具的工作原理及安装、调试 28

4.1 模具的工作原理 28

4.2 模具的安装 29

4.3 试模 29

结论 31

谢 辞 32

参考文献 33

引言

1.选题的依据及意义

随着现代制造技术及高新技术的迅速发展、计算机科技的应用,在工业中模具将要变成生产各种产品不可缺少的重要工艺装备。尤其是在塑料产品的制造和生产过程中,应用塑料模具相当广泛,在各类模具中的重要程度也越来越突显,成为一系列模具设计、制造与研究中最具有表现意义的模具之一。随着注塑模具不断成为生产塑料制造品的主要手段,且不断发展成为最有前景的模具之一。注射成型是现在市场上最具前景、最常用的塑料成型手段之一,因此注塑模具作为塑料模的一种,它将具有相当大的市场需求量。因此我选应急灯注塑模具设计作为我毕业设计选择的课题。

本课题知识点与涉及的知识面较多,应用性强与,如模具设计、三维造型、注塑成型、二维三维软件的应用以及运动仿真。

川公网安备: 51019002004831号

川公网安备: 51019002004831号